Beam Layout Welding Used To Emit Light

It is more popular than its laser beam welding counterpart. However, there are cases where EBW machines prove to be more efficient and advantageous. It's called "I beam" and it can be seen front-facing.

Gulf States Saw & Machinery Co is the global leader in structural steel fabrication technology. Beam Layout Welding machines are a key advantage for steel fabricators. They can optimize tonnage and maintain an edge in the steel industry.

Today, we'll be learning more about H beam welders. In addition, we can help you locate the best, most trusted and most reliable Beam layout welding companies in the industry. Beam layout welding is popular because it's more durable than regular flat plates and has a lot of engineering benefits.

It is more popular than its laser beam welding counterpart. However, there are cases where EBW machines prove to be more efficient and advantageous. It's called "I beam" and it can be seen front-facing.

We sell machine tools, robotics systems, and other fabrication equipment. But we also offer education to ensure our customers remain competitive in a global market. You will be able to stay ahead of the curve with our seminars, factory tours and other programs as a client.

Our specialty is robotic welding and other Industrial applications for Robotics, such as Machine Tending or Material Handling. Capital Robotics' headquarters is located in Atlanta, but we also have a Dallas office that maintains systems and provides training to customers. Capital Robotics has always increased its technical staff, including application engineers, welders, and service engineers.

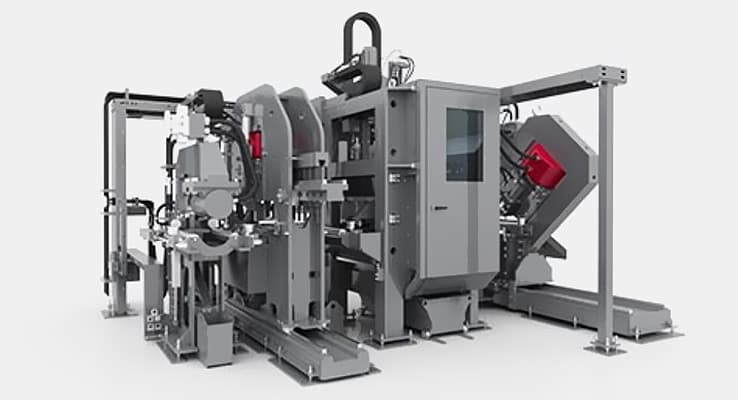

Beam Layout Welding makes it possible to join web sections together with a 100% welded seam. The edges of the two pieces are used as guides and the air cylinders clamp them in place. The grooved copper backup plate is placed against the lower end of the joint. The welding head follows the joint and welds by a single-wire, submergedarc.

There will be no shortage of H beam welder machines on the market. This is especially true when you consider the increasing number of manufacturers. Gulf States Saw & Machinery Co. is the trusted manufacturer in this industry. We have served satisfied clients for more than a decade.

A welded beam consists of three individual sections of steel – a web, a top flange and a bottom flange. These segments are merged together with deep fillet welds to create an incredibly robust building material.